In-Mold Decorations: Integrating Layout and Production Excellence

In-Mold Decorations: Integrating Layout and Production Excellence

Blog Article

Understanding In-Mold Decorations: Methods, Trends, and Finest Practices for Ideal Outcomes

In the world of manufacturing, the art of in-mold designs stands as an essential aspect of product layout and production. As sectors continuously look for ingenious means to improve aesthetic appeal and capability, mastering the ins and outs of in-mold decors has become an essential capability. From choosing the appropriate materials to including sophisticated style fads, the journey towards achieving optimum lead to this domain name is multifaceted. By delving into the methods, fads, and best techniques that underpin successful in-mold decor processes, services can open a realm of possibilities that not only raise the visual attraction of their products however additionally streamline production efficiency and boost customer engagement.

Product Selection

Product selection is a critical element of mastering in-mold decors, as it directly influences the high quality and resilience of the last product. When picking materials for in-mold decors, it is vital to consider aspects such as compatibility with the molding procedure, the preferred visual outcome, and the ecological conditions the item will certainly face.

In addition, the selected product should possess good attachment residential or commercial properties to make certain that the decor sticks firmly to the substrate throughout the molding procedure. Attachment in between the decor and the material is crucial for protecting against delamination and guaranteeing durable aesthetic appeal. Furthermore, products with high warm resistance are liked for in-mold decors, specifically for products that will be subjected to raised temperature levels during their lifecycle. By very carefully picking the ideal material for in-mold decorations, producers can enhance the general top quality and resilience of their products, satisfying the expectations of both clients and end-users.

Layout Technology

A crucial variable in progressing the field of in-mold decors is the continuous exploration and application of design development methods. Design innovation plays an essential role in boosting the visual appeal, functionality, and total top quality of products manufactured making use of in-mold design processes. By including cutting-edge style elements, manufacturers can separate their products in the market, draw in consumers, and stay in advance of competitors.

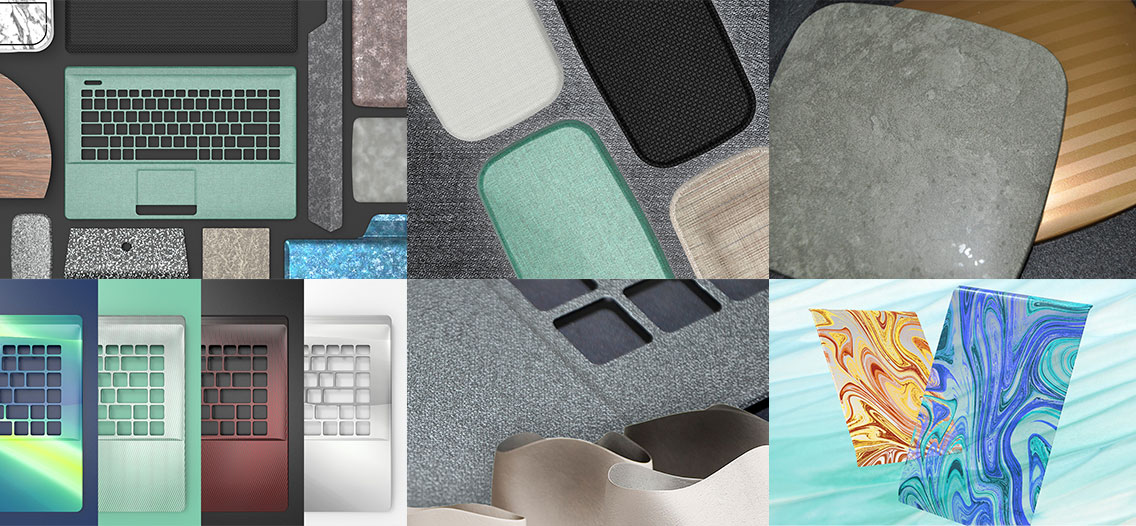

Among the essential aspects of style development in in-mold decorations is the combination of elaborate patterns, appearances, and graphics that were previously testing to accomplish with standard design techniques. Advanced innovations such as 3D printing and digital design tools make it possible for designers to develop complicated and thorough styles that can be flawlessly transferred onto molded parts. Furthermore, the use of lively colors, metallic surfaces, and unique impacts like gloss or matte appearances can even more boost the visual charm of in-mold enhanced items.

Moreover, design advancement expands beyond aesthetic appeals to incorporate functional improvements such as ergonomic forms, integrated functions, and personalized elements that satisfy details individual requirements. By welcoming design development, makers can open new opportunities for creative thinking, item, and customization distinction in the you could try these out affordable landscape of in-mold decors.

Manufacturing Performance

Efficient manufacturing procedures are crucial for converting the ingenious designs created in the field of in-mold decorations into top notch finished items that satisfy market demands and customer assumptions. In the realm of in-mold decorations, manufacturing effectiveness encompasses numerous crucial aspects that add to the general success of the manufacturing procedure.

Automation not only accelerates the production process however likewise boosts accuracy and repeatability, leading to a more uniform and premium end item. On the whole, an alternative technique to manufacturing performance is paramount in optimizing the possibility of in-mold decor strategies and accomplishing optimum outcomes in the competitive market landscape.

High Quality Control Steps

What are the crucial techniques for making certain rigid quality control actions in the realm of in-mold decorations? Quality control procedures are critical in in-mold decor processes to make certain the production of flawless and premium completed items.

Utilizing innovative technologies such as computerized evaluation systems can likewise improve the top quality control process by supplying accurate and reliable data for evaluation. These systems can detect flaws that might be missed out on by hands-on inspections, consequently boosting overall product high quality and uniformity.

Routine training and growth programs for staff members included in the in-mold design procedure can also contribute to preserving high-grade standards. By educating personnel on ideal methods, quality assumptions, and the value of attention to information, firms can cultivate a culture of top quality consciousness throughout the company.

Customer Allure

To enhance the marketability of in-mold decoration products, catering and understanding to customer choices play a vital role in determining their appeal and success. Consumer appeal in in-mold decors is affected by various elements, including design looks, shade options, toughness, and total capability. Customers are significantly looking for customized and distinct products that reflect their originality and design. Providing customization alternatives such as personalized designs, shade variations, and textural elements can dramatically improve the appeal of in-mold decor products.

Final Thought

In-mold decors offer a versatile and effective means to enhance product looks. By carefully selecting materials, welcoming innovative designs, optimizing production processes, carrying out high quality control procedures, and focusing on customer allure, suppliers can attain optimum outcomes. It is crucial for companies to continually adapt and improve their techniques to stay competitive on the market. In-Mold Decorations. Mastering in-mold decorations requires an all natural strategy that takes into consideration all facets of the production process to guarantee success.

In the realm of production, the art of in-mold designs stands as a critical aspect of item style and production. Layout advancement plays a vital role in boosting the visual allure, performance, and total high quality of products produced using in-mold decor processes.One of the vital aspects of style innovation in in-mold decors is the integration of detailed patterns, appearances, and graphics that were previously challenging to attain with typical design approaches.Reliable Get More Info manufacturing processes are important for converting the ingenious layouts developed in the area of in-mold decorations into high-quality completed items that meet market needs and customer expectations. Using customization choices such as individualized layouts, shade variants, and textural elements can dramatically boost the appeal of in-mold design items.

Report this page